"The Cumberland Furnace"

by

Tom Batcha

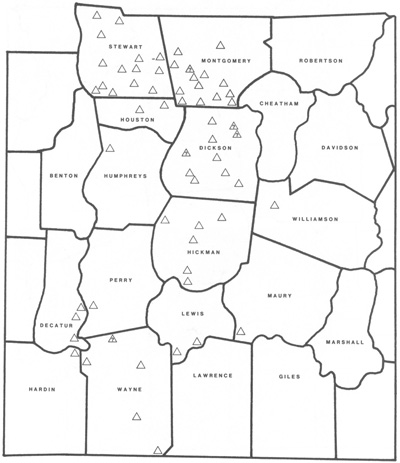

Distribution of furnace sites in the Western Rim

In conjunction with the Mid-Tennessee Gem & Mineral Society, GMS has visited (and will probably visit again) the Cumberland Furnace to collect colorful slag [original text updated by webmaster]. As many of you may know I have studied the topic of iron furnaces for several years and thought I would pass along some information about the Cumberland Furnace as well as the region for those members that will be making the trip to the area.

The Cumberland Furnace is located in the region of Tennessee known as the Highland Western Rim. Found in this region is the Great Western Iron Belt. The belt is 15 to 40 miles wide and stretches north to south through Tennessee for a distance of 115 miles. The iron region includes parts of the counties of Stewart, Montgomery, Houston, Humphreys, Dickson, Perry, Hickman, Lewis, Wayne, Lawrence, and the western most edges of four additional counties encompassing a total area of five thousand square miles. The first furnaces in the region were built in the 1790’s. The high point for furnace operations occurred between the years 1835 – 1860 with the year 1852 having the highest number with 36 furnaces in blast. Furnace operations continued into the 20th century as iron production fluctuated based on market price. The industry remained active until 1959 when the closing of the Warner/Wrigley Furnace in Hickman County marked the end of the era. In all there are 56 recorded and 5 unrecorded furnace sites in the region.

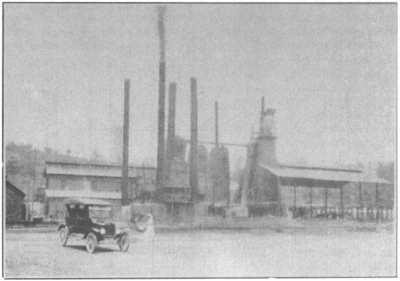

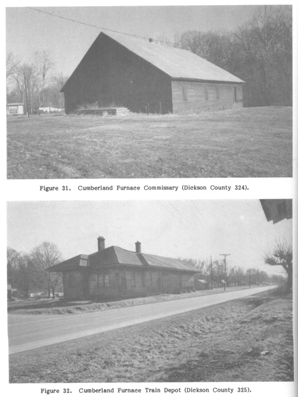

The Cumberland Furnace in Dickson County was the first furnace site to open in the region and had the longest history of operation beginning in 1795 and the final closing in 1936. The site saw three different furnaces constructed over that time, reflecting the changes in technology over the period. One of the first ironmasters in the region was Montgomery Bell. In 1804 he acquired the existing ironworks and its tract of land of 640 acres and operated under the name of Cumberland Ironworks and employed 70 persons. Anthony Vanleer purchased the furnace in the 1820’s and by 1850 was employing 121 persons and operated under the name of Tennessee Ironworks. It is estimated that the second furnace replaced the first at the time Vanleer purchased the site. With Vanleer’s death in 1863, the estate was inherited by his grandchildren Vanleer Kirkman and Mary F. Kirkman. Mary Kirkman married J. P. Drouillard and they purchased her brother’s interest. The J.P. Drouillard Company operated the furnace up until the late 1880s. By 1880 the Drouillard Company employed 250 persons. In 1889 the furnace was purchased by Southern Iron Company and the old furnace was replaced by a modern coke furnace. By 1896 ownership had changed to the Buffalo Iron Company and by the turn of the century it was purchased by the Warner Iron Company. The Warner Company operated the furnace until it closed in 1936.

Warner Iron Company at Cumberland Furnace, 1923

Another topic related to iron furnaces worth mentioning is a description of slag since this will be the focus of what is being collected there [original text updated by webmaster]. Slag was formed in the furnace when the impurities in the iron ore combined with the limestone flux. Since it was lighter it floated on top of the molten iron and was periodically tapped off or drawn off. As it cooled it was broken into irregular lumps and discarded near the furnace. The slag varies in color. A fine sky blue denotes the presence of manganese. Gray slag indicates high grade iron rich in graphite carbon. Dark slag shows the iron was low in graphitic carbon.

The interest in the region’s iron history remains active today. One of the most recent resources is a website known as The Tennessee Iron Furnace Trail. The website location: http://www.tnironfurnacetrail.org/. The site provides historic information as well as being an excellent archive for past and present photographs. You will find that a number of stacks in the region are still standing. The site provides a rough map for their location and pictures of the stacks as they look today. There is enough to keep someone busy for a few days if they tried to take in all of the locations.

For those who will be making the field trip I hope this information will add to the enjoyment of the excursion. Best of Luck and Happy Hunting.

Reference:

(Including Map and Photographs)

Smith, S., Stripling, C., & Brannon, J. (1988). A Cultural Resource Survey of Tennessee’s Western Highland Rim Iron Industry, 1790s—1930s. Tennessee Department of Conservation, Division of Archaeology, Research Series No. 8

Copyright © Georgia Mineral Society, Inc.