DMC Field Trip

If you have any questions about field trips send email toDMC Field Trip

Hosted by the Alabama Mineral & Lapidary Society

Iron Related Tours and Hike

Saturday, February 29, 2020

A few zigs and zags because of last minute changes didn't keep the AMLS from hosting a great trip. It included a tour of Sloss Furnaces and a hike in Red Mountain Park. There was also an iron bowl workshop the night before the trip.

Iron Bowl Workshop

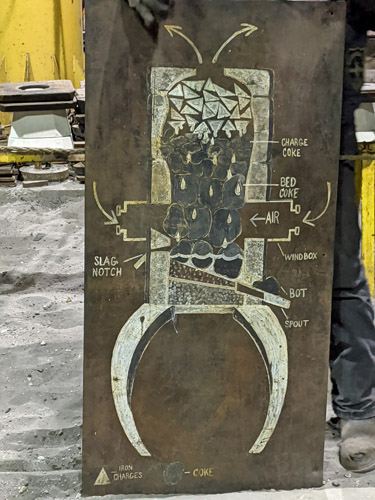

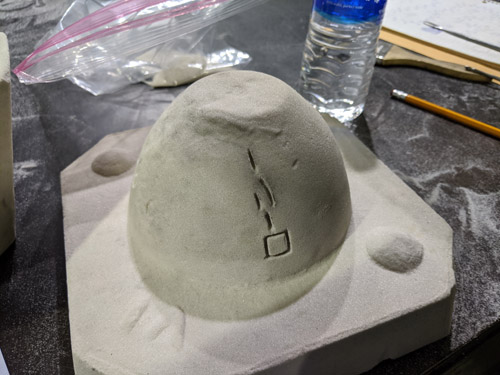

The night before the trip, field trip attendees were invited to participate in an iron bowl workshop at the Metal Arts area of Sloss Furnaces. Before we started working on our bowls, we learned how the mini blast furnace worked and we learned about the materials used in it to produce the iron for our bowls. Then we used metal tools to etch designs into inner and outer forms made of sand held together by a urethane polymer. The two forms were put together to form the bowl mold, then metal artists poured molten iron into them. As the iron cooled and the molds were removed, everyone waited eagerly to see their bowl appear. After the bowls were revealed, we watched as the metal artists emptied the furnace and cooled it down for the next iron pour adventure.

Sloss Furnaces Tour

The trip started at Sloss Furnaces. AMLS member and temporary trip leader Sandra Sullivan welcomed everyone and showed us samples of iron-related rocks. Our tour guide, Ty, explained how the abundance and quality of natural resources in and around Birmingham were perfect for producing iron. As we walked through the site, he told us how iron ore was processed and how the process changed from the time the furnaces were fired up in 1882 through the time the last iron flowed there in 1971. He also told us about the human side of Sloss. The relentless heat of the furnaces, the inherent dangers of working around molten metal, and iniquities among the workers made it a difficult place for the people who worked there. Ty gave us a special tour that not many people get to experience. He even gave us some special gifts!

Red Mountain Park Tour

After the Sloss tour, we regrouped at Red Mountain Park. Our guide Jeff, led us on a tour of a fraction of the 1,500 acres encompassed by the non-profit park. A staggering amount of iron ore was mined in Alabama. Various sources estimate as much as 700 million tons of iron ore were mined in Alabama from the mid-1850's through the 1970's, mostly from the Birmingham area. Jeff showed us various buildings and mining artifacts, explaining what they were for and how they were used. He also took us to some of the mines where the ore was extracted. He talked about how there were different types of ore there, one better than the other, and showed us examples of both. The human aspect of iron ore mining also came to life as Jeff told us about the people who mined the area as well as the people who ran the mining companies.

Lasting Impressions

As I write this report, I realize the experience was a satisfyingly odd way to learn about something -- from end to beginning -- making a bowl out of iron that came from a place like Sloss Furnaces that processed iron ore mined from a place like Red Mountain. By experiencing everything in reverse, each step along the journey added to the prior in a way that peeled back layer by layer the various aspects of iron in Birmingham.

Many Thanks!

There were so many people who made this trip successful. Sandra was a trooper, working hard to recover from a firestorm of last minute difficulties to honor her club's DMC hosting commitment. She brought several examples of local materials related to iron processing for attendees to see, and she told many stories of her family's personal history with Sloss Furnaces.

Marshall and all of the other metal arts artists gave us an unforgettable iron pour experience at the bowl workshop. They welcomed us into their world of metal arts, helped us etch our designs, tamed the dragon that oozed iron for our bowls, and taught us how cool hot iron can be.

Ty was so gracious and generous scheduling a last minute tour of Sloss Furnaces for our group. Our tour was filled with his impressive knowledge and enthusiasm for the history of Sloss, Birmingham, and the people who made that history. He went above and beyond for us and we sincerely appreciate all of his efforts.

Erika at Red Mountain Park worked diligently to help set up a last minute hike for us. Jeff led that hike with a passion for the history of the park that made our journey into the iron ore mining history as fun as it was educational. He (and his wife) capped off our fantastic trip and we thank them for our tour as well as everything they are doing for the park.

Ty and Jeff even managed to entertain the youngest members of our group, truly an accomplishment itself!

Many thanks to everyone who made this trip so enjoyable, including club members from all over the southeast who came together for this wonderful trip!

Iron Bowl Workshop

Photo by Lori Carter

Blast furnace diagram showing what goes in and how it works

Photo by Lori Carter

The dragon coming to life

Photo by Lori Carter

Tapping the first iron pour

Photo by Lori Carter

Feeding the hungry beast

Photo by Lori Carter

Form for the outside of my bowl

Photo by Lori Carter

Form for the inside of my bowl. I etched my name in Japanese upside-down and backwards!

Note the baggie in the background for keeping the sand that came out as I etched my design ;o)

Photo by Lori Carter

Pouring iron into the bowl molds!

Photo by Lori Carter

This iron is about 2300 degrees fahrenheit

Photo by Lori Carter

Bowl mold filled with molten iron

Photo by Lori Carter

Draining the dragon's belly

Photo by Lori Carter

Magic

Photo by Lori Carter

Unmolding a bowl. Notice the "plug" of iron on the top (actually the bottom) of the bowl

Photo by Lori Carter

The plug on this bowl was still glowing!

Photo by Lori Carter

Iron bowls!

Photo by Lori Carter

Outside of my bowl (upside-down to show details).

Since I was in Alabama, I made Cincosaurus cobbi tracks and an Acaste birminghamensis trilobite

Photo by Lori Carter

Inside of my bowl showing the year and my name in Japanese.

I had to write them in the mold upside-down and backwards!

Sloss Furnaces

Photo by Lori Carter

Sloss Furnaces National Historic Landmark

Photo by Lori Carter

Sandra showed us samples of iron-related rocks before the tour

Photo by Lori Carter

Ty started the tour with a brief description of how a a blast furnace works as well as an introduction to

the history of Sloss Furnaces and how that history is intertwined with the history of Birmingham

Photo by Lori Carter

Seeing the furnaces from the outside

Photo by Lori Carter

Inside the stock tunnel where furnace ingredients were staged for loading into the furnaces

Photo by Lori Carter

Looking around the lower end of the skip hoist where ore and other ingredients from the stock tunnel

were loaded into buckets that carried the materials up the skip hoist and into the furnace.

Photo by Lori Carter

Yard where slag (impurities discarded from iron processing) accumulated

Photo by Lori Carter

Checking out the sandy floor of the casting shed where the iron was formed into "pigs"

Photo by Lori Carter

Inside the power house

Photo by Lori Carter

If you can pick up this giant wrench (that was actually used!), you can take it home

Photo by Lori Carter

The generators were enormous

Photo by Lori Carter

Another one of those wrenches!

Photo by Lori Carter

Ty answered all of our questions, and attendees asked a lot of good questions

Photo by Lori Carter

We saw mica used as an insulator in this device

Photo by Lori Carter

Our tour ended with a stroll through a garden of iron art

Red Mountain Park

Photo by Lori Carter

The last part of the trip was a hike in Red Mountain Park to see iron ore mining artifacts and mines

Photo by Lori Carter

Some of the original buildings are still standing

Photo by Lori Carter

Slag wouldn't have been produced here, but may have been used as fill, ballast, or for other purposes

Photo by Lori Carter

Boy scouts built some chairs for weary hikers

Photo by Lori Carter

Jeff explained how cables were used to haul ore from the mine up over a hill then down to the hoist house

Photo by Lori Carter

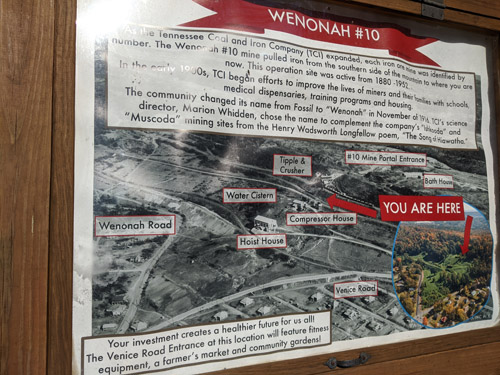

Jeff told us the history of the Number 10 mine, also known as the Wenonah Number 10 mine

Photo by Lori Carter

A control house where we saw big cables used by the hoist

Photo by Lori Carter

We could feel and see misty air rushing out of the last mine of the day

Photo by Lori Carter

More pictures of my bowl -- in case you missed it :o)

Click below for field trip policies

Copyright © Georgia Mineral Society, Inc.